Creality unveiled its flagship products, the K1 and K1 Max, in April 2023. Unlike the budget-friendly Ender 3 series, the K1 series stands out as a fully enclosed high-speed 3D printer with intelligent AI, excelling in both speed and functionality. Significant advancements have been achieved in all aspects, leading to widespread admiration and popularity upon its release. The K1C, as one of the latest flagship members, is set to be released in 2024, with sales commencing on January 25. Branded as the "Champion of Speed and Skill," this model is specifically designed for carbon fiber 3D printing. While it shares many features with the K1 and K1 Max, there are also notable differences. In this article, our goal is to offer a comprehensive overview of all three models so that you can make an informed choice when selecting the 3D printer that best suits your needs. For more detailed information on the K1C, please follow this link. Let's delve into the technical specifications of the K1, K1 Max, and K1C, covering essential machine details, printing parameters, printing speed, filament support, printer features and more. Device Information Printing Parameters Sprinting Speed Supported Filament Nozzle Components Printing Platform Machine Features Let's begin by noting the commonalities among the Creality K1, K1 Max, and K1C printers. The first similarity is that all three printers come almost fully assembled. Setting them up takes just around 20 minutes. After assembly, the touchscreen helps you start automatic calibration and self-testing to check the hardware for issues. If everything's okay, you'll get a prompt to begin your first print. One notable shared feature is the CoreXY design, enhancing motor precision, compacting the machine, and enabling impressive print speeds of up to 600 mm/s with accelerations reaching 20,000 mm/s². The K1, K1 Max, and K1C feature a heated aluminum alloy bed for fast and even heating. The build plate is a flexible smooth PEI sheet, ensures good adhesion for small and large prints. Occasionally, applying glue may enhance adhesion. The enclosed system allows easy printing of high-temperature filaments like ABS and ASA. The printer includes a user-friendly 4.3-inch color touchscreen for previewing loaded models. It comes with a modified Klipper version tuned for Creality printers. An update by Creality lets users enjoy Klipper's benefits, like custom optimization profiles and joining the open-source community for exploring advanced features. The Creality K1, K1 Max, and K1C printers are supported by the official Creality Print slicing software. Additionally, they are compatible with popular 3D printing software such as Cura, Simplify3D, PrusaSlicer, and others. This flexibility allows users to choose the slicing software that best suits their preferences and workflow. However, there are some notable differences between the K1, K1 Max and K1C. Let's take a look at the differences. Regarding build volume, the Creality K1 Max distinguishes itself with a notably larger capacity, as implied by its name — measuring 300 x 300 x 300 mm. This considerable size enables users to effortlessly print large models without the requirement for subsequent separation and assembly. In contrast, both the K1 and K1C share the identical build volume as the standard Ender 3, measuring at 220 x 220 x 250 mm. The K1 Max boasts a robust 1000W rating, significantly higher than the 350W of the K1 and K1C. This increased power capacity enables users to easily upgrade and draw power from the motherboard. In comparison to the K1 and K1C, the K1 Max reaches a temperature of 60℃ in just 90 seconds and maintains consistent heating speeds under both 220V and 110V. This power capacity also facilitates the direct powering of add-ons from the K1 Max motherboard, including the Creality multi-material system currently in development. Both the K1 and K1 Max support a range of filaments, including PLA, Hyper PLA, PETG, ABS, TPU, and PA. The K1C, as indicated by the "C" in its name, stands for "Carbon" and introduces support for wear-resistant filaments like PLA-CF, PA-CF, and PET-CF, offering more filament options. This allows makers to explore and practice 3D scenes with greater versatility. Furthermore, the K1C incorporates an all-metal integrated design for both its nozzle and throat. In contrast to the K1, this design guarantees smoother material discharge, an extended service life, and straightforward maintenance. The all-metal proximal extruder has undergone further evolution, delivering consistent extrusion force and meticulous control over consumable flow to ensure the production of high-quality models. The K1, K1 Max, and K1C all incorporate intelligent AI functions, while with differing configurations. For instance, the K1's Smart AI camera is available as an optional through accessory upgrades, while the K1C includes the AI camera as a standard feature. The K1 Max stands out by offering both "AI LiDAR" and "AI Camera," making it the most advanced in terms of product function configuration. In the case of the K1 Max, AI-assisted features play a crucial role in elevating print quality and minimizing the risk of print failures, resulting in filament savings. The LiDAR sensors meticulously map the initial layer, ensuring a robust start with excellent adhesion and assisting in flow calibration. Moreover, the integrated AI-assisted camera oversees prints, identifies failures, and records time-lapse photography. The K1 base model is priced at £499, while the K1C is available for order at £512.00 (5% off, regular price is £539.00), and the advanced features of the K1 Max come with a price about £300 more. While these upgrades are considered conveniences, others notably enhance print quality and user safety. Let's delve into the key enhancements. Firstly, although the K1 comes with a ventilation fan, the K1 Max elevates it with the inclusion of a carbon air filter. Additionally, the K1 Max features a larger build volume 300 x 300 x 300 mm. Finally, the K1 Max has advanced AI assistance functions "AI LiDAR" and "AI Camera," ensuring the success rate of printing. However, you have the option to enhance the configuration of the K1 by acquiring AI camera accessories only £29.00, a more cost-effective choice compared to directly purchasing the K1 Max. Determining the better value for money among the K1, K1 Max, and K1C ultimately depends on your personal preferences and priorities. If cost-effectiveness is your top priority, the K1 is the most affordable choice among the three, offering excellent printing speed and quality. In summary, although the K1, K1 Max, and K1C have many similarities, it's important to recognize that the differences between them represent substantial upgrades, often considered as luxury features. In conclusion, the Creality K1, K1 Max, and K1C are high-end 3D printers offering not only impressive printing speed but also exceptional print quality. Take action now and pick the right 3D printer that aligns with your specific needs and preferences.

Part1: K1 vs. K1 Max vs. K1C Specification at A Glance

Type

Model

K1

K1 Max

K1C

Product Dimensions

355*355*480mm

435*462*526mm

355*355*482mm

Package Dimensions

415*415*550mm

508*508*608mm

428*428*567mm

Net Weight

12.5kg

18kg

12.4kg

Gross Weight

16kg

23kg

16kg

Display Screen

4.3" color touch screen

4.3" color touch screen

4.3" color touch screen

Electronic

Rated Input Voltage

100-120V~/200-240V~

100-240V~

100-240V~, 50/60Hz

Output Voltage

24V DC

24V DC

24V DC

Rated Power

350W

1000W

350W

Printing Technology

FDM

FDM

FDM

Build Volume

220*220*250mm

300*300*300mm

220*220*250mm

Printing Accuracy

100±0.1mm

100mm±0.1

100±0.1mm

Layer Height

0.1-0.35mm

0.1-0.35mm

0.1-0.35mm

Typical Printing Speed

300mm/s

300mm/s

300mm/s

Max. Printing Speed

≤600mm/s

≤600mm/s

≤600mm/s

Acceleration

≤20000mm/s²

≤20000mm/s²

≤20000mm/s²

Filament Diameter

1.75mm

1.75mm

1.75mm

High speed

ABS/Hyper PLA

ABS/Hyper PLA

ABS/Hyper PLA

Regular

PLA/PETG/PET

PLA/PETG/PET

PLA/PETG/PET

Flexible

TPU

TPU

TPU

Strength

PA/ABS/ASA/PC

PA/ABS/ASA/PC

PA/ABS/ASA/PC

Wear-resistant

/

/

PLA-CF/PA-CF/PET-CF

Extruder Count

1

1

1

Extruder

Dual-gear direct drive extruder

Metal direct drive extruder

Nozzle Material

Copper Alloy

Hardened Steel

Tri-metal Nozzle Integrated

Nozzle Diameter

0.4mm (Standard)

0.4mm (Standard)

0.4mm (Standard)

Nozzle Optional

0.6mm, 0.8mm

0.6mm, 0.8mm

0.6mm, 0.8mm

Nozzle Temperature

300℃

300℃

300℃

Build Surface

PEI Flexible build plate

PEI Flexible build plate

PEI Flexible build plate

Heatbed Temperature

100℃

100℃

100℃

Heating time

30℃-300℃ ( ≤ 6min. )

30℃-300℃ ( ≤ 3min. )

30℃-300℃ ( ≤ 6min. )

Silent Mainboard

Yes

Yes

Yes

Power Loss Recovery

√

√

√

Filament Runout Sensor

√

√

√

Dual Z-axis

3 Z-axis

3 Z-axis

3 Z-axis

Leveling Mode

Hands-free auto leveling

Dual hands-free auto leveling

Hands-free auto leveling

Remote Printing

Yes

Yes

Yes

Enclosure

Yes

Yes

Yes

Air Purifier

/

√

√

Sleep Mode

/

/

√

Software

File Transfer

USB drive, WiFi

USB drive, WiFi

USB drive, WiFi

Printable File Format

G-Code

G-Code

G-Code

File Formats for Slicing

STL, OBJ, AMF

STL, OBJ, AMF

STL, OBJ, 3MF

Slicing Software

Creality Print; Cura, Simplify3D, PrusaSlicer

UI Languages

10 Languages

10 Languages

10 Languages

Smart AI

AI Camera

Optional

√

√

AI LiDAR

/

√

/

Part2: Similarities Overview: K1 vs. K1 Max vs. K1C

1. Printing Speed

2. Build Plate

3. UI Design

4. Software

Part3: K1 vs. K1 Max vs. K1C Differences Details Comparison

1. Build Volume

2. Rated Power & Mainboard

3. Filament Support

4. Smart AI Assistance

5. Price

Part4: Which One is Right for You? K1, K1 Max, K1C?

【Rapid Printing: 600mm/s Speed 20000mm/s² Acceleration】

【Effortless Auto-Leveling】

【Solid Unibody Frame】

【Auxiliary Cooling Fan in Chamber】

【Intelligent Control: Remote Control and Self-Tests】

【User-Friendly Design: Suits Beginners and Experts】

【Rapid Printing: 600mm/s Speed 20000mm/s² Acceleration】

【Core XY Nimble Setup for Speed: Agile and Swift】

【Ceramic Heater Encircles the Hotend: Max. 32mm³/s Flow】

【Model Cooling by Dual Fans】

【Max Capacity 300x300x300mm, Efficient Use of Space】

【AI-assisted Carefree Printing】

【Rapid Printing: 600mm/s Speed 20000mm/s² Acceleration】

【Clog-free All-metal Extruder Kit】

【Supporting Carbon Fiber Filaments】

【Observant Al Camera】

【Pleasant Air While Printing】

【Quieter Than Ever, Silent Mode ≤ 45dB*】

For those seeking to create large-size models and utilize advanced AI functions for hassle-free printing, the K1 Max is the ideal option. It encompasses all the impressive features of the K1 with additional upgrades, albeit at a relatively higher price.

If you're interested in exploring model creation with carbon fiber filaments and prefer a relaxed and quiet printing environment, the K1C is a great option. It comes with upgraded materials for the nozzle and extruder, allowing for silent mode operation.Conclusion

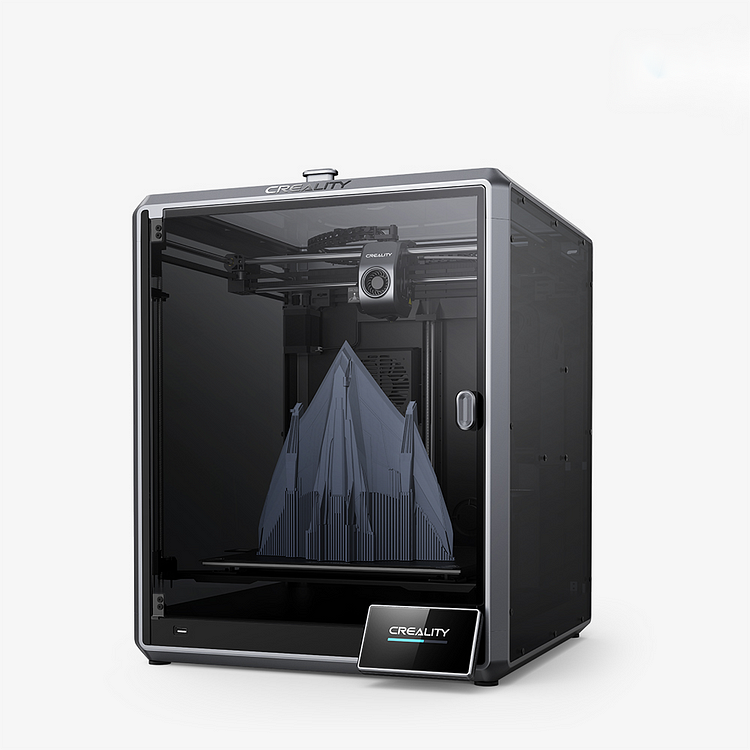

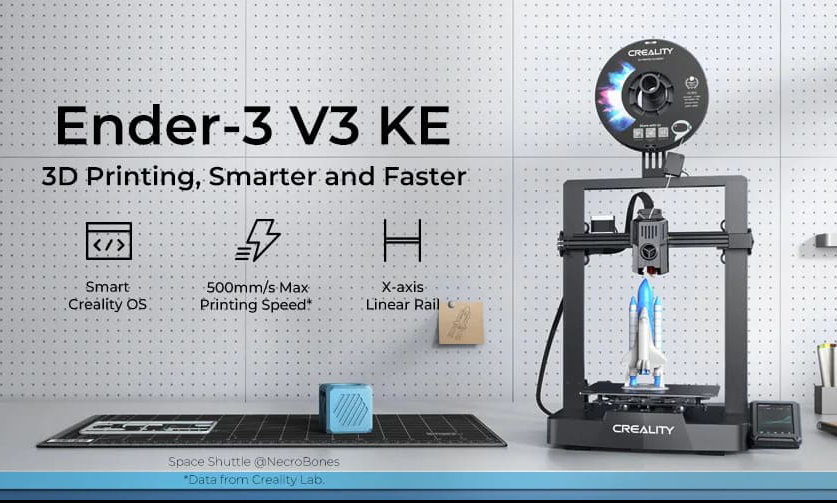

The Ender-3 V3 KE. Building upon the legacy of the Ender-3 series, this new release comes with extensive upgrades and a touch of intelligence, making it a great choice for both beginners and hobbyists.

The K1C, as one of the latest flagship members, is set to be released in 2024, with sales commencing on January 25. Branded as the "Champion of Speed and Skill," this model is specifically designed for carbon fiber 3D printing. While it shares many features with the K1 and K1 Max, there are also notable differences.

Creality K1C 3D printer is an enclosed Core XY FDM printer capable of speeds up to 600 mm/s. Designed to compete with the industry's top 3D printers, the K1C sets a new standard with its all-metal hotend, upgraded motor system, and innovative build plate.