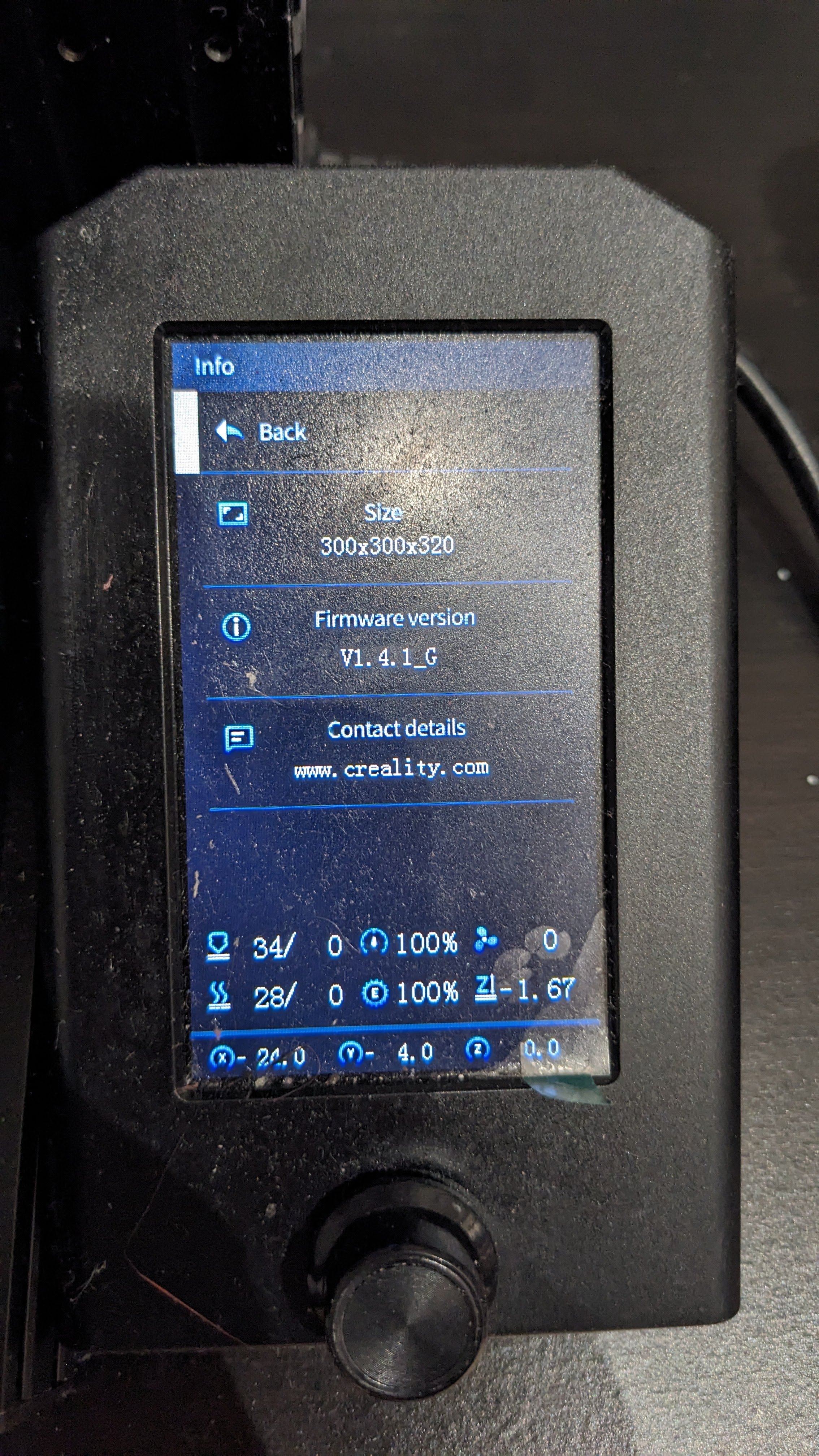

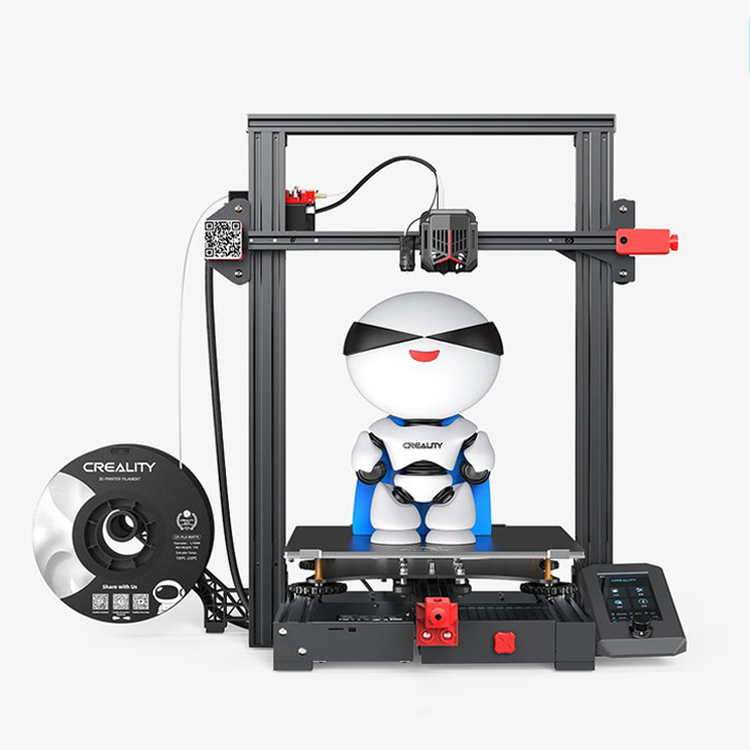

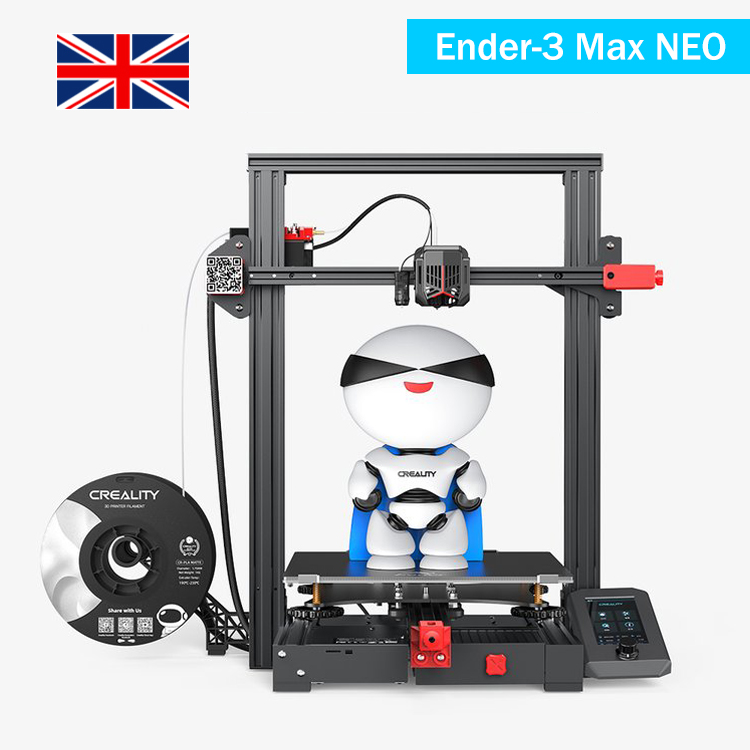

Ender-3 Max NEO 3D Printer | 300*300*320mm

£ GBP

£ GBP

Please select product attributes before purchasing~~

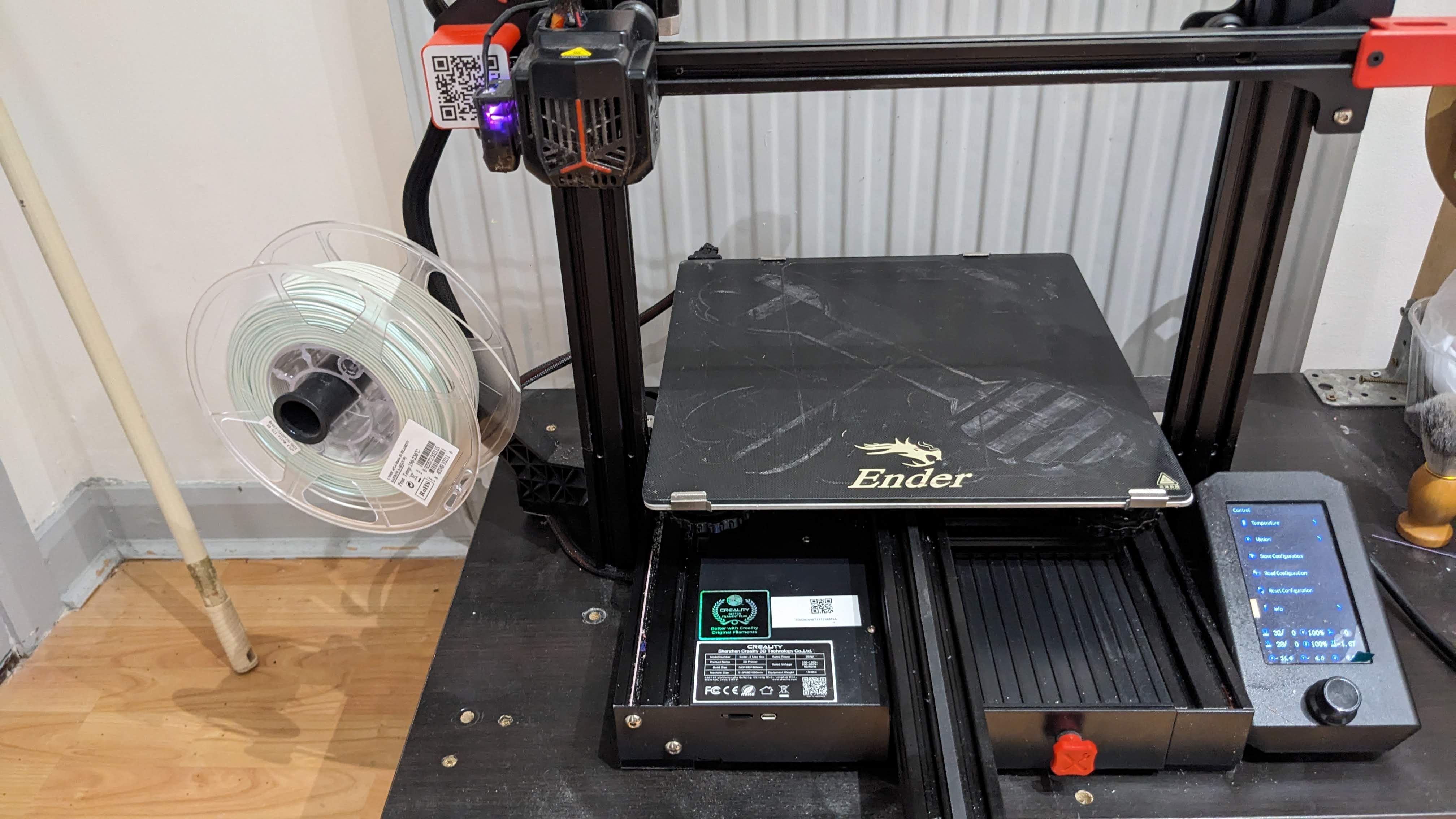

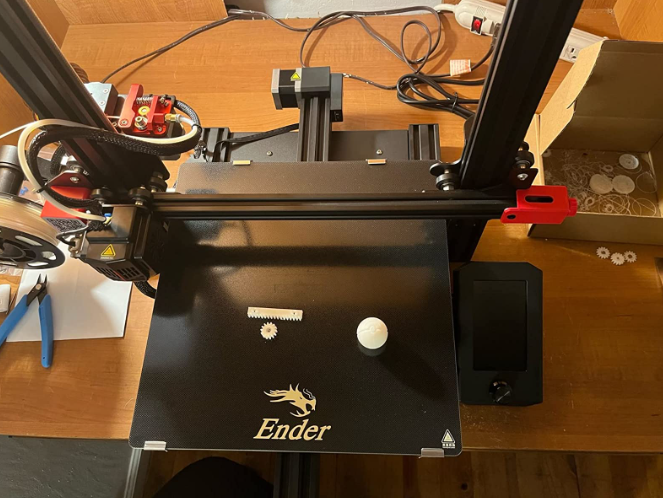

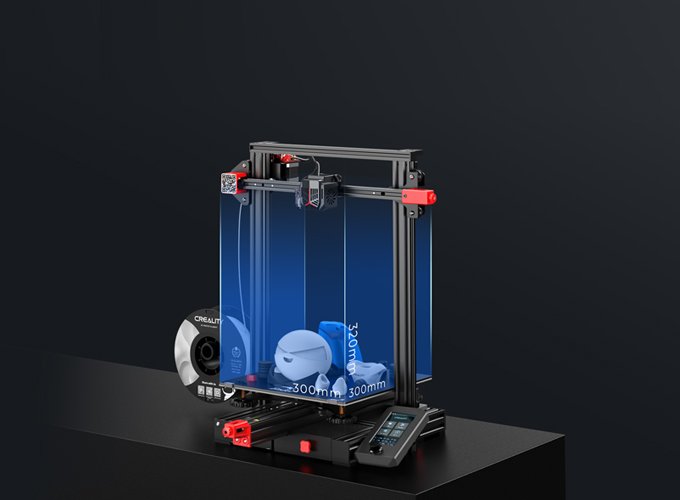

More Creative with Larger Build Volume

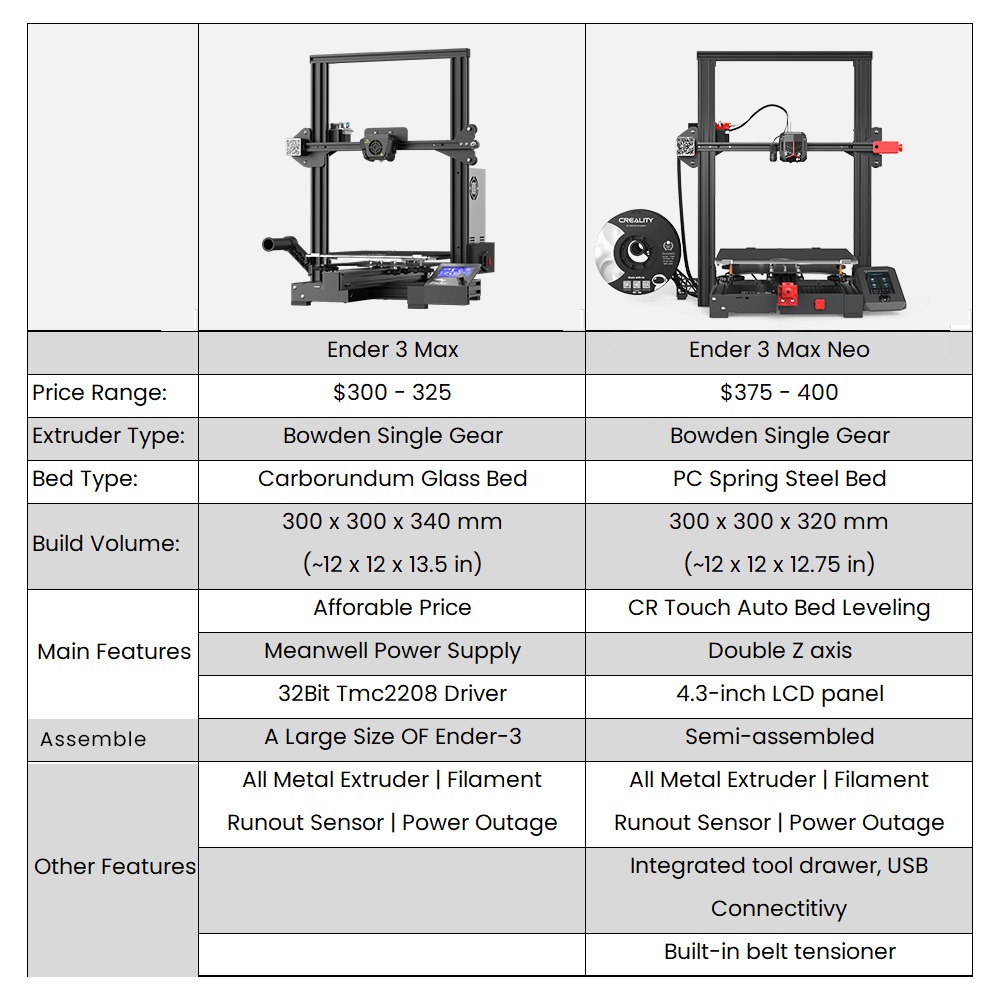

The 300*300*320 mm build volume enables large model printing and small parts printing at a time, vastly improving the efficiency and offering more creation possibilities.

Ultra-stable with Dual Z-axes

Perfect coordination among dual Z-axes, timing belt and dual motors guarantees the stability and higher printing precision.

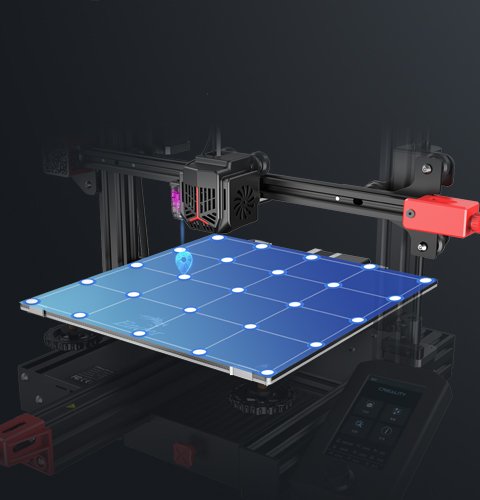

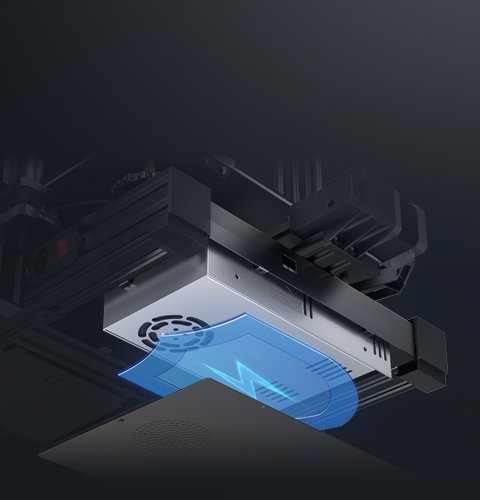

CR Touch Frees You From Leveling

CR Touch auto-leveling improves the efficiency by automatically measuring and adjusting the 25-point print height on the heat bed, making leveling much easier.

3 Steps Assembly, Start Printing Now

Preassembly has solved those hassles and worries of parts assembly. Start your print with just 3 steps.

Knob to Experience Something New

The 4.3-inch color knob screen that will dim out in 4 minutes without operation is an energy saver. Optimized with icons, the UI is more vivid.

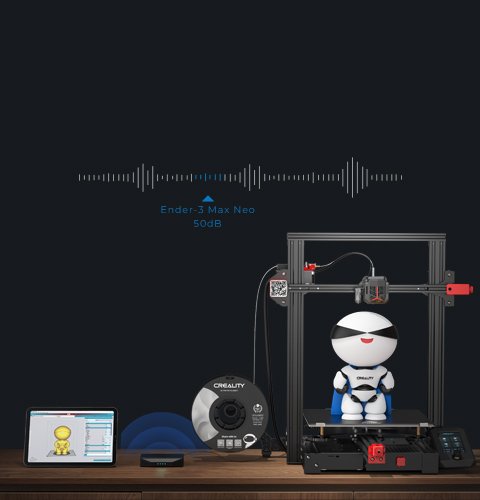

Get Rid of Noisiness

Equipped with a 32-bit silent mainboard, the noise exposure is lower than 50dB. Enjoy cozy printing and have fun.

Quality Power Supply Values Your Safety

The 350W high-quality built-in power supply is more secure and reliable, improving the stability and the sense of integration.

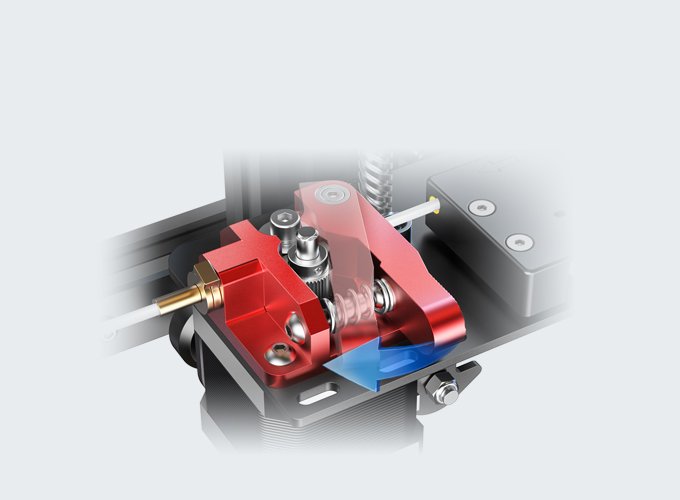

Smooth Feeding with Full-metal Extruder

The full-metal Bowden extruder is more durable and has greater extrusion force. Say "No" to materials that are prone to cracking! Assisted by gears, filaments' loading and withdrawal is not a problem.

Ender 3 Max NEO Descriptions:

Based on 8 reviews

Write A Review

Ask A Question